Sandstone

About Sandstone

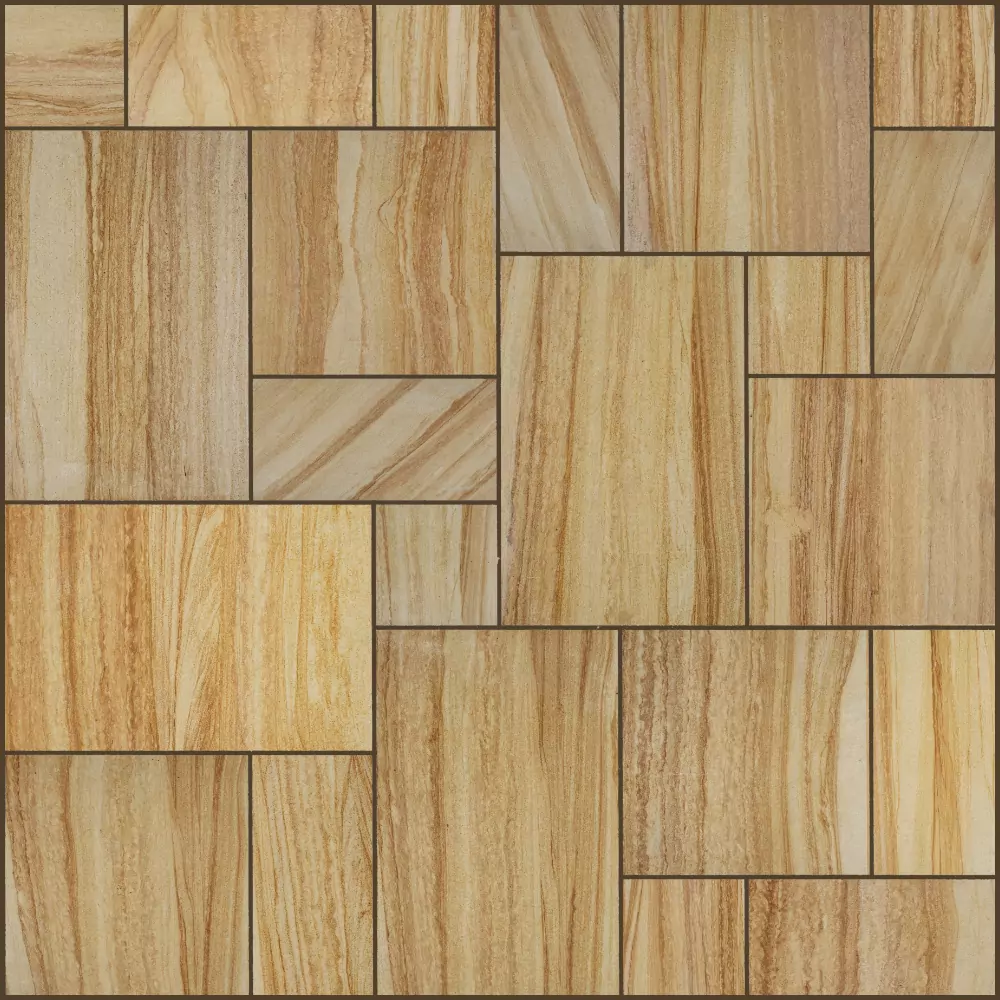

Sandstone is a sedimentary rock consisting of rock grains or sand-sized minerals. It is a well-known building and landscaping material due to its aesthetic appeal, versatility, and durability. Sandstone comes in various colours, including browns, yellows, reds, greys, and tans. The colour variations of sandstone give it a unique and natural look.

Sandstone is resistant to weathering and has a high absorption rate, making it ideal for outdoor applications such as paving, patio and driveway areas. The uniform texture of sandstone also makes it a versatile material to suit various design requirements with different cuts and shapes. In addition, the soft nature of sandstone makes it easy to work with, yet it has a high compression strength, which makes it durable and long-lasting.

Indian sandstone paving is a cost-effective solution if you are looking to create an attractive and durable patio or driveway. Indian sandstone paving comes in several colours, including Raj Green, Kandla Grey, Rippon Buff, Fossil Mint, and Autumn Brown, giving you a wide range of options. In addition, each sandstone paving slab is unique, with its colour palette, profile and veining, making it a perfect choice for those seeking a natural and rustic look.

Architects and builders have used sandstone in several iconic structures throughout history, including the Red Fort in Delhi, the outer-complex area of the Taj Mahal, and the White House, which showcases its durability and longevity. So whether you’re looking to create a rural countryside feel or a more modern look, sandstone is an excellent choice for those looking for a cost-effective and efficient solution for their outdoor space.

Have any Questions?

We supply premium quality products at the most competitive prices.

Yes, we offer free samples.

The products are almost similar as shown in the pictures yet colour variation exists because it is natural stone and the beauty is in the inconsistency in colour.

We deal with various types of natural stone such as sandstone, limestone, slate, and porcelain. All these stones can be processed in specific sizes and finish.

Our delivery time for standard products is 4 weeks from the date of order.